High-Speed Single Plate Open Cam Paper Cup Machine

$10,300.00

Key Features: High-Speed Paper Cup Machine

- ✓

High-Speed Production: Achieves a stable output of 100-120 pcs/min, significantly boosting your productivity.

- ✓

Exceptional Versatility: Covers a full range of cup sizes from 1.5 to 16 OZ with exchangeable molds. Compatible with both single and double PE-coated paper.

- ✓

Advanced Ultrasonic Sealing: Utilizes an ultrasonic heater for side sealing, resulting in a stronger, more energy-efficient, and cleaner bond.

- ✓

Robust & Reliable Design: Built with a durable open cam system, it handles a wide paper weight range (140-350 gsm), ensuring consistent performance for the long term.

Enquire Wholesale Price

🎬 Video Showcase

⚙️ Machine Overview

📋 Product Specifications

* Note: This machine must be operated with an air compressor for normal production.

📏 Paper Cup Dimensions

☕ Finished Products

🏭 Workshop Photos

📦 Packing & Shipping

🔌 Supporting Equipment

For pricing on the Disposable Paper Cup Digital Printer, and to learn about the complete process flow and supporting equipment, please contact our customer service.

⬇️ Product Processing Flow

Step 1: Raw Material Procurement

The process begins with the procurement of raw materials, specifically pre-cut paper cup fans. The market price for these materials typically ranges from $1,200 to $1,400 USD per ton. The total number of cups that can be produced per ton varies depending on the size and paper weight of the final product, as well as whether it is a single-wall (single PE coated) or double-wall design.

Step 2: Custom Printing

Next, the blank paper cup fans are fed into a printing machine. Based on the artwork provided by the client, we can print custom logos, branding information, or any personalized designs directly onto the paper fans to meet the client’s promotional needs.

Step 3: Fully Automatic Forming

Once printed, the paper fans are loaded into our fully automatic paper cup forming machine. The machine handles all core processes automatically: side sealing, bottom punching and heating, bottom knurling (sealing), and rim curling, efficiently forming the paper fan into its final shape.

Step 4: Finished Product & Packaging

The result is a high-quality, finished paper cup. The formed cups are then automatically counted and stacked, preparing them for the subsequent packaging and shipping phase, ready for delivery to the client or for direct market entry.

Additional information

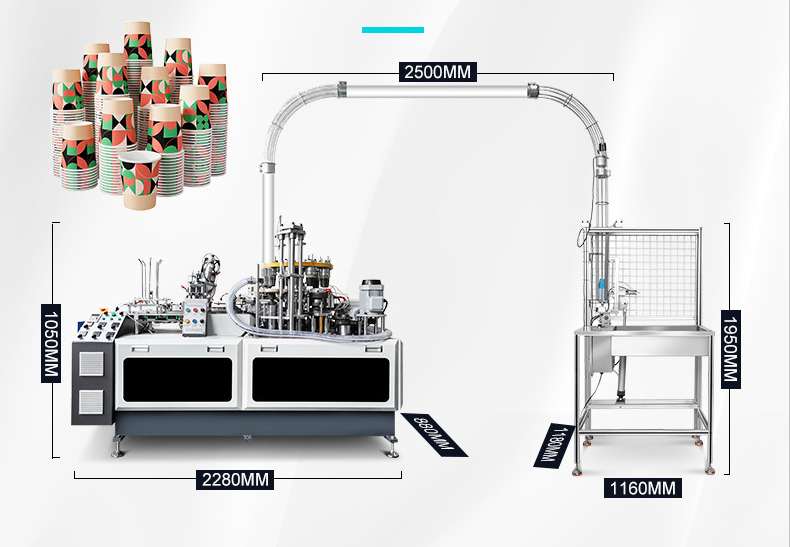

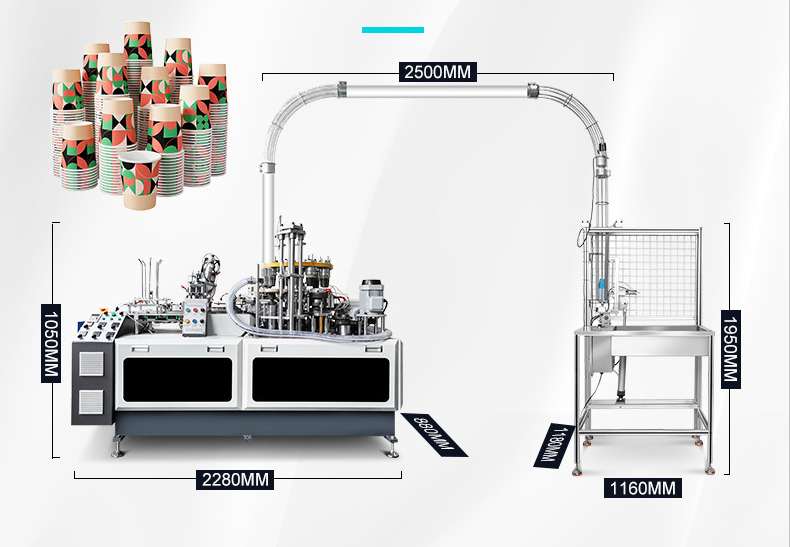

| Packing Size | Machine Size: 1050*880*2280mm |

|---|---|

| Total Power | 6KW 60HZ, 380V |

| Rated Speed | 100-120 pcs/min |

| Total Weight | GW/NW: 1600KG / 1500KG |

| Paper Weight | 140 – 350 gsm |