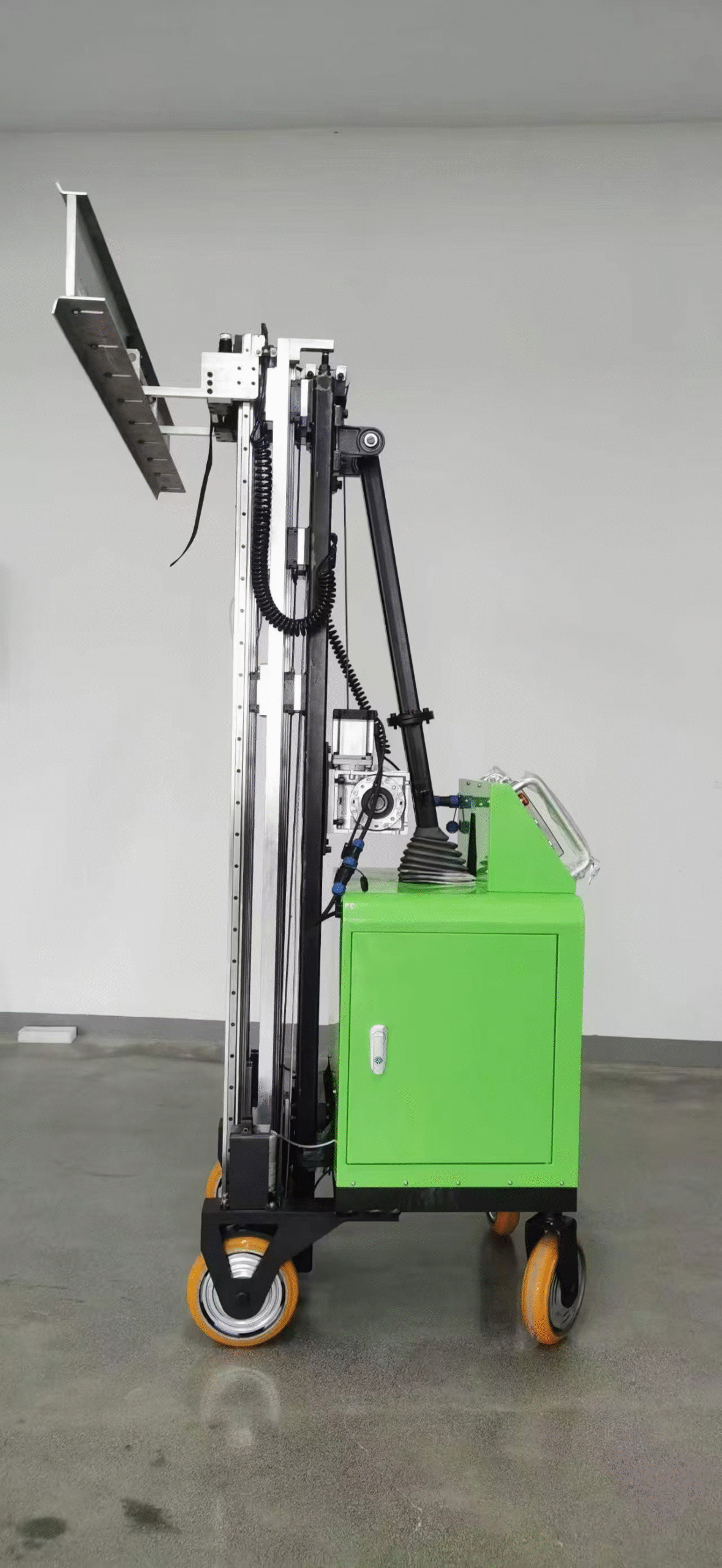

Fully Automatic Wall Plastering Robot

$4,950.00

- 🤖

Fully Automatic Operation: Dramatically reduces labor costs and project time by automating the entire plastering process from leveling to finishing.

- ⭐

Superior & Consistent Finish: Engineered with intelligent sensors and a 1.3m trowel to deliver a perfectly flat, smooth, and flawless wall surface every time.

- 🔋

Powerful & Cordless: Equipped with a high-capacity 48V LiFePO4 battery and a 0.75kW brushless servo motor for maximum mobility and performance on any job site.

- 👉

Intuitive Touch Screen Control: Features a user-friendly interface for simple setup, angle adjustment, and operation, making it accessible to any operator.

- 🚀

High Efficiency: Capable of plastering hundreds of square meters per day, making it the ultimate solution for boosting productivity and meeting tight deadlines.

Enquire Wholesale Price

🎬 Video Showcase

📋 Product Specifications

🖼️ Product Showcase

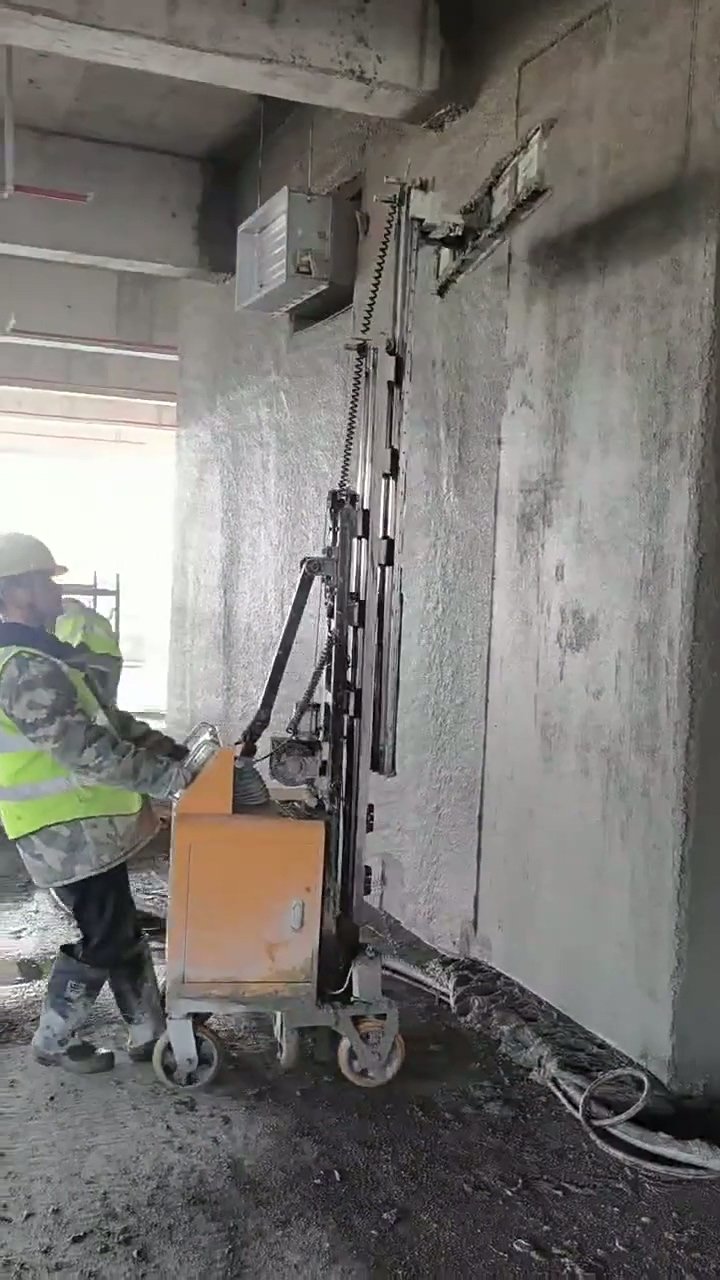

🏗️ On-Site Application

📦 Packing & Shipping

🏢 Application Range & Key Features

🎯 Application Range

This machine is specifically designed for interior wall plastering in residential buildings, office buildings, and commercial structures. It offers versatility across multiple wall types and plaster materials.

✅ Compatible Wall Types:

- Concrete walls

- Brick and mortar walls

- Hollow walls

- Lightweight brick walls

- Non-fired brick walls

🧱 Suitable Plaster Materials:

- White sand plaster

- Stone powder

- Cement plaster

- Foam mortar

- Dry powder mortar

- Gypsum plaster

Specification Range: Suitable for plaster thickness up to 3cm and wall heights up to 3 meters.

⚙️ Core Functions

Our advanced fully automatic wall plastering machine delivers comprehensive coverage with precision positioning and superior finish quality.

- Complete Coverage: Plasters walls entirely from floor to ceiling, leaving no gaps or unfinished areas.

- Corner Precision: Handles both internal and external corners with professional accuracy.

- Rapid Positioning: Achieves vertical and horizontal positioning in just 10 seconds using dual support poles combined with traditional leveling methods.

- Superior Quality: Vibration technology and enlarged trowel design eliminate common issues like hollowing and cracking that occur with manual plastering.

- Enhanced Efficiency: Significantly improves material utilization rates and project completion times.

🔧 Advanced Features

🛠️ Manganese Steel Trowel

Rust-resistant, deformation-proof, oxidation-resistant manganese steel surface with excellent rigidity and extended lifespan.

⚙️ Rack and Pinion Drive

Smooth vertical movement system with low failure rate, delivering superior wall finish quality compared to traditional cable-operated machines.

🔧 Modular Vertical Poles

Plug-and-play height adjustment system allows quick setup for different ceiling heights and easy transportation when disassembled.

📳 Vibration Motor

High-frequency stainless steel vibration motor ensures proper material compression and smooth application, eliminating hollowing and cracking.

🎮 Dual Control System

Both remote control and manual operation capabilities provide flexible control options for enhanced operator convenience.

⚠️ Important Safety Precautions

📖 Before Operation

- Read the Manual: Always read and understand the user manual thoroughly before operating the machine.

- Battery Check: Ensure the battery is fully charged before starting work to avoid interruptions. Store the battery in a cool, dry place.

- Surface Preparation: Ensure the wall surface is clean, free of dust, and properly moistened if required by the plaster type.

🦺 During Operation

- Safety Equipment: Always wear appropriate Personal Protective Equipment (PPE), including safety glasses, gloves, and steel-toed boots.

- Stable Ground: Operate the machine only on a flat, stable, and level surface to ensure machine stability and plastering accuracy.

- Proper Positioning: Allow 10 seconds for complete vertical and horizontal positioning before starting the plastering process.

🧽 After Operation

- Immediate Cleaning: Clean the machine, especially the trowel and mortar application areas, immediately after use to prevent plaster from hardening and causing damage.

- Battery Care: Properly store and maintain the battery according to manufacturer guidelines to extend its lifespan.

- Regular Maintenance: Perform routine maintenance checks on the vibration motor, rack and pinion system, and electrical components.